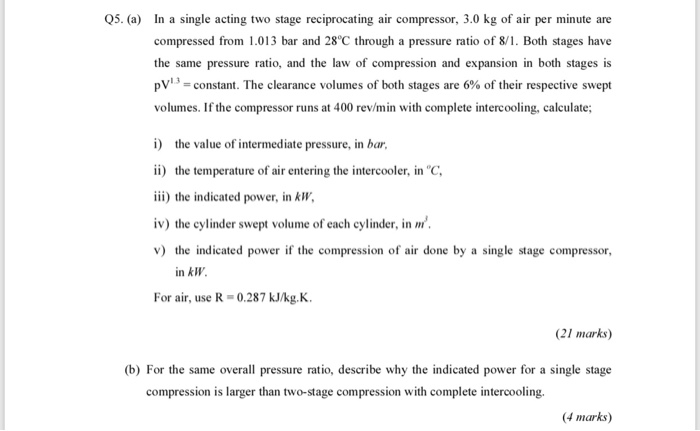

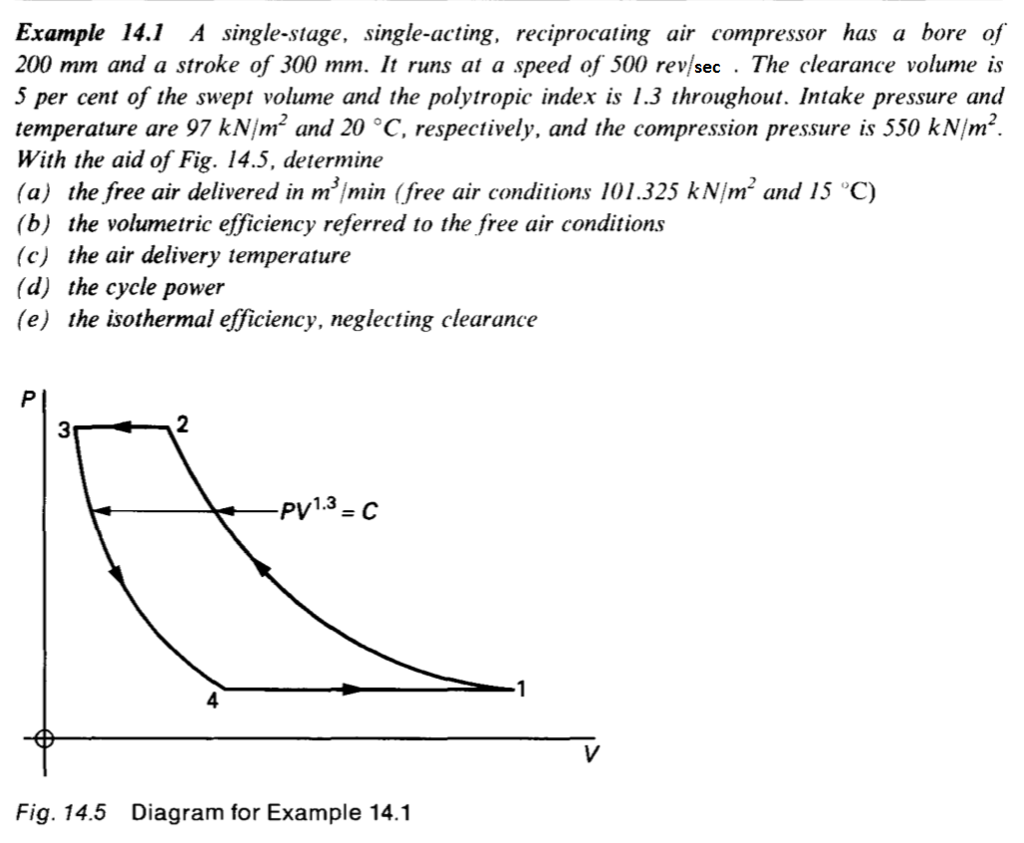

While straightforward this setup is limited in its efficiency and capacity for delivering high volumes of pressurized air.

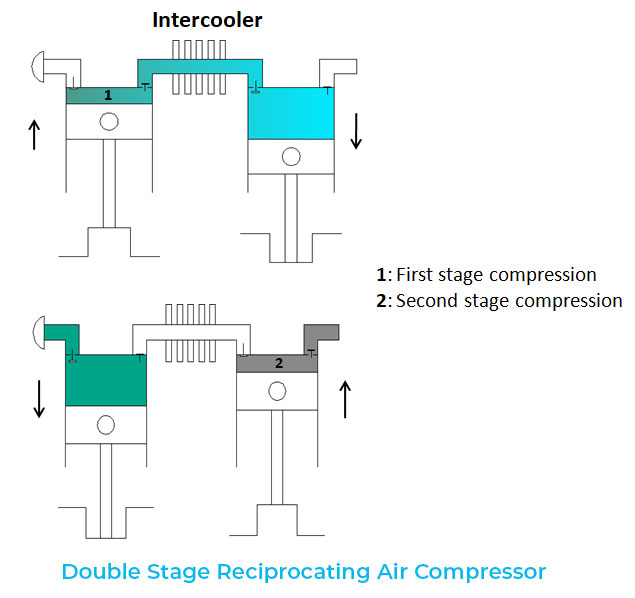

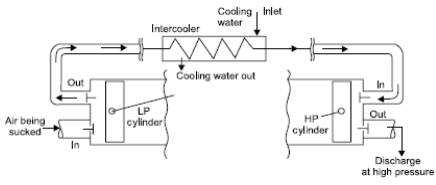

Two stage reciprocating air compressor with intercooler.

The process within a two stage compressor alternately referred to as a dual stage compressor is similar to that of a single stage but with one variation.

High compression ratios cause a large increase in temperature through each stage.

The air after compression in the l p.

It s instead sent to a smaller piston for a second stroke this time at roughly 175 psi.

The experiments of a two double cylinder reciprocating compressor system with air water and different intercoolants were performed.

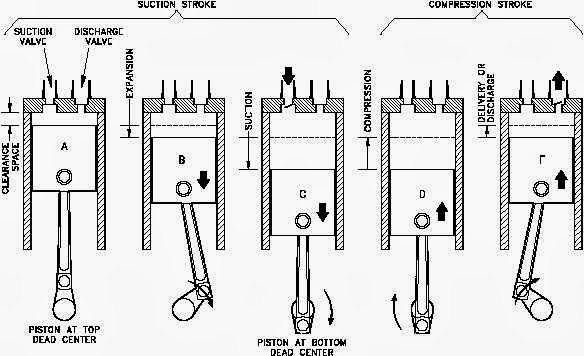

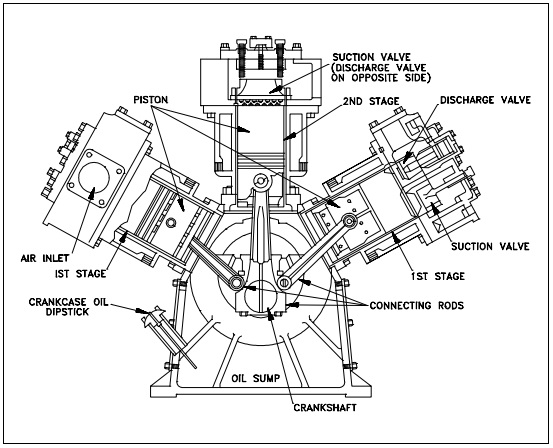

Reciprocating piston compressors use a cylinder to force air into a chamber where it is compressed.

To reduce the temperature of the gas at the inlet to the next stage.

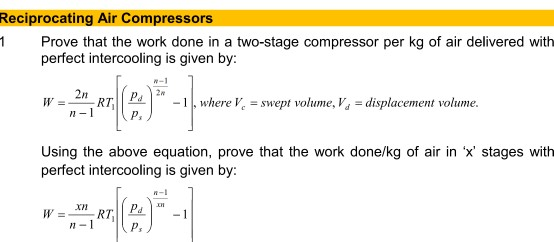

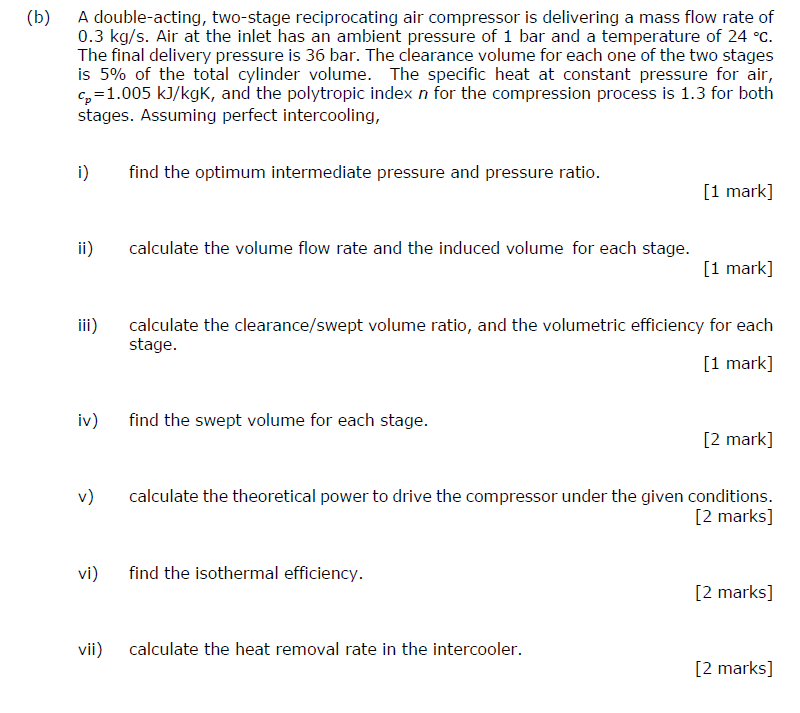

Work required to be done by a two stage reciprocating air compressor with complete intercooling is given by.

First of all the fresh air is sucked from the atmosphere in the low pressure l p cylinder during its suction stroke at intake pressure p 1 and temperature t 1.

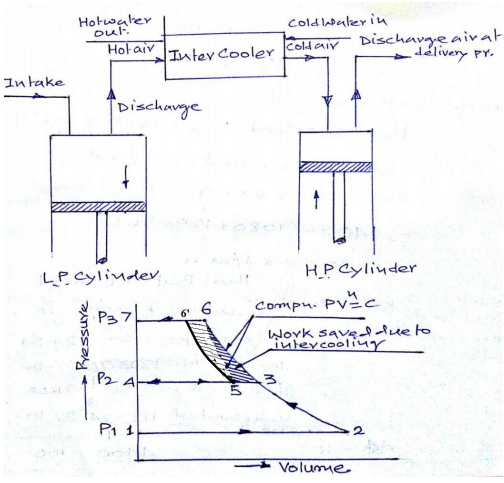

The multistage compressor with intercooler in between is shown in figure.

Two stage reciprocating air compressor with intercooler.

The inter cooling reduces the volume of air which used to increase due to heat.

The ribbed air lines between cylinders and into the tank on the following husky compressor are an example of a basic intercooler.

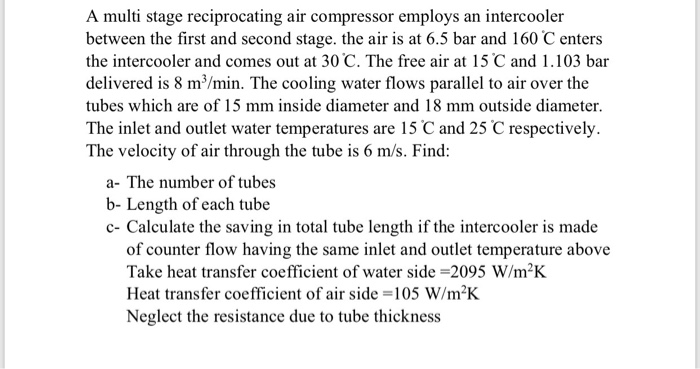

Intercoolers in multi stage units.

Of two stage reciprocating air compressor by providing water cooling source radiator coolant and ethylene glycol and results are compared.

It reduces the cost of compressor.

In a multi stage compression system the intercoolers serve two functions.

The compressed air from the first stage enters the intercooler where it is cooled.

If the intake pressure and delivery pressure are constant then the least value of the intermediate or intercooler pressure may be obtained by differentiating the above equation with respect to intercooler pressure.

The compressed air isn t sent to a storage tank.

The ribbed air lines offer more surface to the surrounding air transferring heat from the air in the line to the atmosphere.

It is used to reduce the temperature of compressed air during the compression stages.